CIP #26 - Jobsite Addition of Water

WHAT is Jobsite Addition of Water?

Jobsite addition of water is the addition of water to ready mixed concrete in a truck mixer after arrival at the location of the concrete placement. Such tempering of concrete may be done with a portion of the design mixing water which was held back during the initial mixing, or with water in excess of the design mixing water, at the request of the purchaser.

WHY is Water Added at the Jobsite?

When concrete arrives at the jobsite with a slump that is lower than that allowed by design or specification and/or is of such consistency so as to adversely affect the placeability of the concrete, water can be added to the concrete to bring the slump up to an acceptable or specified level. This can be done when the truck arrives on the jobsite as long as the specified slump and/or water-cement ratio is not exceeded. Such an addition of water is in accordance with ASTM C 94, Standard Specification for Ready Mixed Concrete.

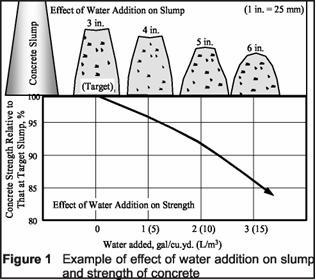

The ready mixed concrete supplier designs the concrete mixture according to industry standards to provide the intended performance. Addition of water in excess of the design mixing water will affect concrete properties, such as reducing strength (Figure 1), and increasing its susceptibility to cracking. If the purchaser requests additional water, in excess of the design mix, the purchaser assumes responsibility for the resulting concrete quality. The alternative of using a water reducing admixture or superplacticizer to increase concrete slump should be considered. Provided segregation is avoided, increasing the slump of concrete using admixtures usually will not significantly alter concrete properties.

HOW to Add Water at the Jobsite?

|

1. The maximum allowable slump of the concrete must be specified or determined from the specified nominal slump plus tolerances.

2. Prior to discharging concrete on the job, the actual slump of the concrete must be estimated or determined. If the slump is measured, it should be

on a sample from the first ¼ cu. yd. (0.2 m³) of discharged concrete and the result used as an indicator of concrete consistency and not an

acceptance test. Tests for acceptance of concrete should be made in accordance with ASTM C 172.

3. At the jobsite, water should be added to the entire batch so that the volume of concrete being retempered is known. A rule of thumb that works

reasonably well is: 1 gallon, or roughly 10 lb., of water per cubic yard for 1 inch increase in slump (5 liters, or 5 kg, of water per cubic meter for

25 mm increase in slump).

4. All water added to the concrete on the jobsite must be measured and recorded.

5. ASTM C 94 requires an additional 30 revolutions of the mixer drum at mixing speed after the addition of water. In fact, 10 revolutions will be

sufficient if the truck is able to mix at 20 revolutions per minute (rpm) or faster.

6. The amount of water added should be controlled so that the maximum slump and/or water-cement ratio, as indicated in the specification, is not

exceeded. After more than a small portion of the concrete is discharged, no water addition is permitted.

7. Upon obtaining the desired slump and/or maximum water-cement ratio, no further addition of water on the jobsite is permitted.

8. A pre-concreting conference should be held to establish proper procedures to be followed, to determine who is authorized to request a water addition, and to define the method to be used for documentation of

water added at the jobsite.

|

ASTM C 94 Jobsite Water Addition

1. Establish the maximum allowable slump and water content permitted by the job specification.

2. Estimate or determine the concrete slump from the first portion of concrete discharged from the truck.

3. Add an amount of water such that the maximum slump or water-cement ratio according to the specification is not exceeded.

4. Measure and record the amount of water added. Water in excess of that permitted above should be authorized by a designated representative of the purchaser.

5. Mix the concrete for 30 revolutions of the mixer drum at mixing speed.

6. Do not add water if: ® The maximum water-cement ratio is reached, ® The maximum slump is obtained, or ® More than ¼ cu.yd. (0.2 m³) has been discharged from the mixer.

|

References

1.

![]() ASTM

C 94, Standard Specification for Ready Mixed Concrete, ASTM, West Conshohocken,

PA.

ASTM

C 94, Standard Specification for Ready Mixed Concrete, ASTM, West Conshohocken,

PA.

2. NRMCA Publication 186, “Ready Mixed Concrete” Richard D. Gaynor, Silver Spring, Maryland.

3. NRMCAQC2—Appendix on Agenda for a Pre-Placement Conference, Silver Spring, Maryland.

4. NRMCA Publication 188, ‘Truck Mixer Driver’s Manual, ’ Silver Spring, Maryland.

5. “Adding Water to the Mix: It’s Not all Bad,” Eugene O. Goeb, Concrete Products, January 1994.

6. “Adjusting Slump in the Field,” Bruce A. Suprenant, Concrete Construction, January 1994.

7. “Effect of Prolonged Mixing on the Compressive Strength of Concrete with Fly Ash and/or Chemical Admixtures,” Dan Ravina, submitted for publication, ACI

Concrete International, 1995.

1995

![]()