CIP #22 - Grout

WHAT is Grout?

ACI defines grout as “A mixture of cementitious material and water, with or without aggregate, proportioned to produce a pourable consistency without segregation of the constituents.” Grout may also contain fly ash, slag, and liquid admixtures.

The terms grout and mortar are frequently used interchangeably, but there are clear distinctions. Grout need not contain aggregate, whereas mortar contains fine aggregate. Grout is supplied in a pourable consistency, whereas mortar is not. Grout fills space, whereas mortar bonds elements together, as in masonry construction.

Grout is often identified by its application. Some examples are: bonded pre-stressed tendon grout, auger cast pile grout, masonry grout, and pre-placed aggregate grout. Controlled low-strength material (flowable fill) is a type of grout.

WHY is Grout Used?

Grout is used to fill space or cavities and provide continuity between building elements. In some applications, grout will act in a structural capacity, such as in reinforced masonry construction. In building construction, grout can improve fire ratings, acoustic performance, and blast resistance, and improve the thermal mass properties of the building elements.

In projects where small quantities of grout are required, it is proportioned and mixed on site. The ready mixed concrete producer is generally called upon when large quantities are needed.

HOW to Specify Grout?

For masonry grout, ASTM C 476 provides prescribed proportions by loose volumes that are convenient for small quantities of grout mixed on-site. Alternatively, ASTM C 476 has provisions for establishing grout proportions on the basis of specified compressive strength. The specified compressive strength must be at least 2000 psi. Grout mixtures meeting the proportion table of ASTM C 476 have high cement contents and tend to produce much higher strengths than specified compressive strength requirements of ASTM C 476, ACI 530 or Model Codes. Two types of masonry grouts are defined in ASTM C 476: fine grout with aggregates smaller than ⅜ inch (9.9 mm), and coarse grout that allows aggregate sizes of up to ½ inch (12.5 mm). Choice of grout type depends primarily on the clear dimensions of the space being filled by the grout. Grouting of masonry construction should comply with the governing building code provisions. Information on grouts for masonry construction is available from the National Concrete Masonry Association (NCMA).

When grout is ordered from a ready mixed concrete producer, the specifications should be based on consistency and compressive strength. Converting loose volume proportions into batch weights per cubic yard is subject to errors and can lead to controversies on the job. Specifications should address the addition of any required admixtures for grout. Conditions of delivery, such as temperature, time limits, and policies on job site addition of water, should be specified. The contractor will need to ensure that the grout consistency is sufficiently flowable. Testing frequency and methods of acceptance must be covered in specifications.

HOW to Test Grout?

The consistency of grout affects its strength and other properties. It is critical that grout consistency permit the complete filling of void space without segregation of ingredients.

Consistency of masonry grout may be measured with a slump cone (ASTM C 143), and slumps of 8-11 in. are generally required for both fine and coarse grout. Self consolidating grout is a highly fluid and stable grout mix that does not require consolidation. These grouts are tested using the slump flow test, ASTM C 1611, that measures the spread of the grout using the slump cone.

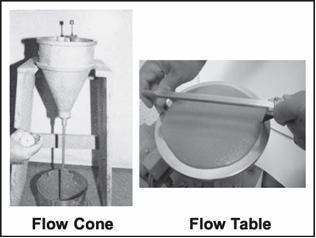

For other types of grouts without aggregate, or only fine aggregate passing a No. 8 sieve, consistency is best determined with a flow cone

(ASTM C 939). For flow values exceeding 35 seconds, use the flow table in ASTM C 109, modified to use 5 drops in 3 seconds.

Masonry grout (“blockfill”) for strength test specimens should be cast in molds formed by masonry units having the same absorption characteristics and moisture content as the units used in construction (ASTM C 1019). Never use nonabsorbent cube or cylinder molds for this purpose.

Strength of other types of grout is determined using 2 in. cubes per ASTM C 942. Method C 942 allows for field preparation, recognizes fluid consistency, and also affords a means for determining compressive strength of grouts that contain expansive agents or grout fluidifiers. This is extremely important since “expansive” grouts can lose substantial compressive strengths if cubes are not confined. However, cylindrical specimens (6 x 12 in. or

4 x 8 in.) may give more reliable results for grouts containing coarse aggregate.

Special-application grouts often require modification of standard test procedures. All such modifications should be noted in the specifications and discussed prior to the start of the job.

References

1. ![]() “Cement

and Concrete Terminology,” ACI Committee 1 16R, A CI Manual of Concrete

Practice, Part 1.

“Cement

and Concrete Terminology,” ACI Committee 1 16R, A CI Manual of Concrete

Practice, Part 1.

2. Cementitious Grouts and Grouting, S. H. Kosmatka, Portland Cement Association, 1990.

3. ASTM C 476, “Standard Specification for Grout for Masonry,” and ASTM C 1019, “Standard Method of Sampling and Testing Grout”, Annual Book of ASTM

3. Standards, Vol. 04.05, ASTM International, West Conshohocken, PA, www.astm.org.

4. ASTM C 143, C 939, C 942, C 1611, Annual Book of ASTM Standards, Vol 04.02.

5. ASTM C 109, Annual Book of ASTM Standards, Vol. 04.01.

6. Hedstrom, E. G., and Hogan, M. B., “The Properties of Masonry Grout in Concrete Masonry,” Masonry: Components to Assemblages, ASTM STP 1063, ed. John

H. Matthys, 1990, pp. 47-62.

7. “Building Code Requirements for Masonry Structures (ACI 530.1-05/AS CE 6-05/TMS 602-05) and Specifications for Masonry Structures (ACI 530.1-05/ASCE 6

-05/TMS 602-05),” ACI-ASCE Standards, American Concrete Institute/American Society of Civil Engineers/The Masonry Society, 2005.

8. NCMA TEK 9-4A, Grout for Concrete Masonry, TEK 3-2A, Grouting Concrete Masonry Walls and TEX 18-8B, Grout Quality Assurance, National Concrete Masonry

Association, Herndon, VA, www.ncma.org.

1993, 2005

![]()