CIP #25 - Corrosion of Steel in Concrete

WHAT is Corrosion of Steel?

ASTM terminology (G 15) defines corrosion as “the chemical or electrochemical reaction between a material, usually a metal, and its environment that produces a deterioration of the material and its properties.” For steel embedded in concrete, corrosion results in the formation of rust which has two to four times the volume of the original steel and none of its good mechanical properties. Corrosion also produces pits or holes in the surface of reinforcing steel, reducing strength capacity as a result of the reduced cross-sectional area.

WHY is Corrosion of Steel a Concern?

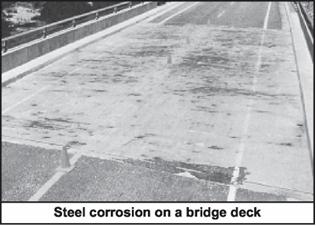

Reinforced concrete uses steel to provide the tensile properties that are needed in structural concrete. It prevents the failure of concrete structures which are subjected to tensile and flexural stresses due to traffic, winds, dead loads, and thermal cycling. However, when reinforcement corrodes, the formation of rust leads to a loss of bond between the steel and the concrete and subsequent delamination and spalling. If left unchecked, the integrity of the structure can be affected. Reduction in the cross-sectional area of steel reduces its strength capacity. This is especially detrimental to the performance of tensioned strands in pre-stressed concrete.

WHY does Steel in Concrete Corrode?

Steel in concrete is usually in a non-corroding, passive condition. However, steel-reinforced concrete is often used in severe environments where sea water or deicing salts are present. When chloride moves into the concrete, it disrupts the passive layer protecting the steel, causing it to rust and pit.

Carbonation of concrete is another cause of steel corrosion. When concrete carbonates to the level of the steel rebar, the normally alkaline environment, which protects steel from corrosion, is replaced by a more neutral environment. Under these conditions the steel is not passive and rapid corrosion begins. The rate of corrosion due to carbonated concrete cover is slower than chloride-induced corrosion.

Occasionally, a lack of oxygen surrounding the steel rebar will cause the metal to dissolve, leaving a low pH liquid.

HOW to Prevent Corrosion?

► Quality Concrete Practices

The first defense against corrosion of steel in concrete is quality concrete and sufficient concrete cover over the reinforcing bars. Quality concrete has a water-tocementitious material ratio (w/cm) that is low enough to slow down the penetration of chloride salts and the development of carbonation. The w/c ratio should be less than 0.50 to slow the rate of carbonation and less than 0.40 to minimize chloride penetration. Concretes with low w/c ratios can be produced by (1) increasing the cement content; (2) reducing the water content by using water reducers and superplasticizers; or (3) by using larger amounts of fly ash, slag, or other cementitious materials. Additionally, the use of concrete ingredients containing chlorides should be limited. The ACI 318 Building Code provides limits on the maximum amount of soluble chlorides in the concrete mix.

Another ingredient for good quality concrete is air entrainment. It is necessary to protect the concrete from freezing and thawing damage. Air entrainment also reduces bleeding and the corresponding increased permeability due to the bleed channels. Spalling and scaling can accelerate corrosion damage of the embedded reinforcing bars. Proper scheduling of finishing operations is needed to ensure that the concrete does not scale, spall, or crack excessively.

The correct amount of steel will help keep cracks tight. ACI 224 helps the design engineer to minimize the formation of cracks that could be detrimental to embedded steel. In general, the maximum allowable crack widths are 0.007 inch in deicing salt environments and 0.006 inch in marine environments.

Adequate cover over reinforcing steel is also an important factor. Chloride penetration and carbonation will occur in the outer surface of even low permeability concretes. Increasing the cover will delay the onset of corrosion. For example, the time for chloride ions to reach a steel rebar at 2 inches from the surface is four times that with a 1 inch cover. ACI 318 recommends a minimum of 1.5 inches of cover for most structures, and increases it to 2 inches of cover for protection from deicing salts. ACI 357 recommends 2.5 inches of minimum cover in marine environments. Larger aggregates require more cover. For aggregates greater than .75 inch, a rule of thumb is to add to the nominal maximum aggregate size .75 inch of cover for deicing salt exposure, or 1.75 inch of cover for marine exposure. For example, concrete with 1 inch aggregate in a marine exposure should have a 2.75 inch minimum cover.

The concrete must be adequately consolidated and cured. Moist curing for a minimum of seven days at 70°F is needed for concrete with a 0.40 w/c ratio, whereas six months is needed for a 0.60 w/c ratio to obtain equivalent performance. Numerous studies show that concrete porosity is reduced significantly with increased curing times and, correspondingly, corrosion resistance is improved.

► Modified Concretes and Corrosion Protection Systems

Increased corrosion resistance can also come about by the use of concrete additives. Silica fume, fly ash, and blast-furnace slag reduce the permeability of the concrete to the penetration of chloride ions. Corrosion inhibitors, such as calcium nitrite, act to prevent corrosion in the presence of chloride ions. In all cases, they are added to quality concrete at w/c less than or equal to 0.45.

Water repellents may reduce the ingress of moisture and chlorides to a limited extent. However, ACI 222 indicates that these are not effective in providing longterm protection. Since good quality concrete already has a low permeability, the additional benefits of water repellents are not as significant.

Other protection techniques include protective membranes, cathodic protection, epoxy-coated reinforcing bars, and concrete sealers (if reapplied every four to five years).

|

HOW to Limit Corrosion

® Use good quality concrete air-entrained with a w/c of 0.40, or less.

® Use a minimum concrete cover of 1.5 inches and at least 0.75 inch larger than the nominal maximum size of the coarse aggregate.

® Increase the minimum cover to 2 inches for deicing salt exposure and to 2.5 inches for marine exposure.

® Ensure that the concrete is adequately cured.

® Use fly ash, blast-furnace slag, or silica fume and/or a proven corrosion inhibitor.

|

References

1. “Building Code Requirements for Reinforced Concrete,” ACI 318, American Concrete Institute, Farmington Hills, MI.

2. “Corrosion of Metals in Concrete,” American Concrete Institute, Farmington Hills, MI.

3. “Control of Cracking in Concrete Structures,” ACI 224R, American Concrete Institute, Farmington Hills, MI.

4. Design and Construction of Fixed Offshore Concrete Structures,” ACI 357R, American Concrete Institute, Farmington Hills, MI.

5. Perenchio, W.F., “Corrosion of Reinforcing Steel,” ASTM STP 169C, 1994, pp. 164-172.

6. Whiting, D., ed., Paul Klieger Symposium on Performance of Concrete, ACI SP-122, 1990, 499 pp.

7. Berke, N.S., “Corrosion Inhibitors in Concrete,” Concrete International, Vol. 13, No. 7, 1991, pp. 24-27.

8. Berke, N.S., Pfeifer, D.W., and Weil, T.G., “Protection Against Chloride Induced Corrosion,” Concrete International, Vol. 10, No. 12, 1988, pp. 44-55.

1995

![]()