CIP #9 - Low Concrete Cylinder Strength

WHAT Constitutes Low Cylinder Strength?

Strength test results of concrete cylinders are used as the basis of acceptance of ready-mixed concrete when a strength requirement is specified. Cylinders are molded from a sample of fresh concrete, cured in standard conditions and tested at a particular age, as indicated in the specification, usually at 28 days. Procedures must be in accordance with ASTM standards. The average strength of a set of 2 or 3 cylinders made from the same concrete sample and tested at 28 days constitutes one test. In some cases cylinders are tested at 7 days to get an early indication of the potential strength, but these test results are not to be used for concrete acceptance. Cylinders used for acceptance of concrete should not be confused with field-cured cylinders, which are made to check early-age strength in the structure to strip forms and continue construction activity.

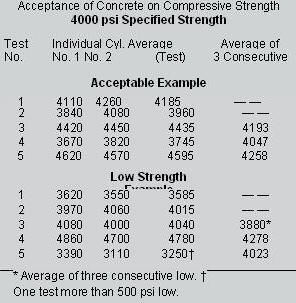

The ACI Building Code, ACI 318, and the Standard Specifications for Structural Concrete, ACI 301, recognize that when mixtures are proportioned to meet the requirements of the standards, low-strength results will occur about once or twice in 100 tests due to normal variability. Under these provisions, for specified strength less than 5000 psi (35 MPa), concrete is acceptable and complies with the specification if:

a) No single test is lower than the specified strength by more than 500 psi (3.5 MPa), and

b) The average of three consecutive tests equals or exceeds the specified strength.

See the example in the table. If an average of three consecutive tests in sequence falls below the specified strength, steps must be taken to increase the strength of the concrete. If a single test falls more than 500 psi (3.5 MPa) below the specified strength, an investigation should be made to ensure structural adequacy of that portion of the structure, and again, steps taken to increase the strength level.

WHY are Compressive Tests Low?

Two major reasons for low compressive strength test results:

a) Improper cylinder handling, curing and testing are found to contribute in the majority of low-strength results.

b) Reduced concrete strength due to an error in production, or the addition of too much water to the concrete on the job due to delays in placement or requests for wet concrete. High air content can also

be a cause of low strength.

In the event of low compressive strength test results, collect all test reports and analyze the results before taking action. Look at the pattern of strength results. Does the sequence actually violate compliance with the specification as discussed above? Do the test reports give any clue to the cause? The strength range of two or three cylinders prepared from the same sample should rarely exceed 8.0% or 9.5% of the average, respectively. Look at the slump, air content, concrete and ambient temperatures, number of days cylinders were left in the field, procedures used for initial curing in the field and subsequent curing in the lab and any reported cylinder defects.

|

Effect of Non-Standard Curing on Compressive Strength (Ref.5) |

If the deficiency justifies investigation, first verify testing accuracy and then compare the structural requirements with the measured strength. If testing is

deficient or if strength is greater than that actually needed in that portion of the structure, there is little point in investigating the in-place strength. However, if procedures conform to the standards and the strength as specified is required for the structural capacity of the member in question, further investigation of the in-place concrete may be required (See CIP 10 on Strength of In-Place Concrete).

Have testing procedures been conducted in accordance with the ASTM standards? Minor deficiencies in curing cylinders in mild weather will probably not affect strength much, but if major violations are discovered, large reductions in strength can occur. Almost all deficiencies in handling and testing cylinders will lower strength. A number of violations may combine to cause significant reductions in measured strength. Some of the more significant factors are improperly finished surfaces, initial curing over 80°F (27°C); frozen cylinders; extra days in the field; impact during transportation; delay in curing at the lab; improper caps; and insufficient care in breaking cylinders.

The laboratory should be held responsible for deficiencies in its procedures. Use of certified field-testing technicians and laboratory personnel is essential; construction workers untrained in concrete testing must not make and handle cylinders. All labs should meet ASTM C 1077 criteria for laboratories testing concrete and concrete aggregates and be inspected by the Cement and Concrete Reference Laboratory (CCRL) laboratory inspection or an equivalent program. Field testing personnel must have a current ACI Grade I Field Testing Technician certification or equivalent. Laboratory personnel should have the ACI Grade I and II Laboratory Testing Technician and/or the ACI Strength Testing Certification, or equivalent.

HOW to make Standard Cylinder Tests?

All of the detailed steps from obtaining a sample, through molding, curing, transporting, testing and reporting cylinder testing are important. The following are critical procedures in the proper application of the ASTM Standards for strength tests of fieldmade, laboratory-cured cylinders.

a) Sample concrete falling from chute in two increments, from the middle part of the load, after some has been discharged.

b) Transport sample to the location of curing for the first day.

c) Remix the sample to ensure homogeneity.

d) Use molds conforming to standards.

e) Using a standard rod or vibrator, consolidate concrete in two or three equal layers, as required, and tap sides of the mold to close rod holes.

f) Finish tops smooth and level to allow thin caps.

g) If necessary, move cylinders immediately after molding; support the bottom.

h) For initial curing of cylinders at the jobsite during the first 24 to 48 hours, store cylinders in a moist environment maintained at 60 to 80°F (16 to 27°C). If feasible, immerse the molded cylinders in

water maintained within this temperature range. Curing boxes without temperature controls can overheat and result in lower strengths.

i) If the cylinders are stored exposed to the environment, keep out of direct sunlight and protect from loss of moisture.

j) Carefully transport one day old cylinders to the laboratory; handle gently.

k) At the laboratory, de-mold the cylinders, transfer identifying marking and promptly place in moist curing at 73 ±3°F (23 ±2°C).

l) Cure cylinders in the laboratory in accordance with ASTM C 31; maintain water on cylinder surfaces at all times.

m) Determine the mass of the cylinder and record it. This information is useful in troubleshooting low strength problems.

n) Caps on cylinders must be flat and the average thickness less than ¼-inch (6-mm) and preferably less than ⅛-inch (3-mm). This is especially significant when testing concrete with strength

exceeding 7000 psi (48 MPa).

o) Use minimum 5000 psi (35 MPa) capping material. Restrict the reuse of sulfur capping compound.

p) Wait at least 2 hours and preferably longer for sulfur caps to harden. Sulfur caps aged for 1 to 2 days often result in higher strength, especially when testing concrete with strength exceeding 5000 psi

(35 MPa).

q) When using neoprene pad caps, ensure that the appropriate Durometer hardness is used for the strength level tested; the pad caps have been qualified for use; pads are not worn and the permitted

number of reuses have not been exceeded; see ASTM C 1231. Worn pads will reduce the measured strength.

r) Ensure that the testing machine is calibrated.

s) Measure cylinder diameter and check cap planeness.

t) Center cylinder on the testing machine and use proper loading rate.

u) Break the cylinder to complete failure. Observe failure pattern; vertical cracks through the cap or a chip off the side indicate improper load distribution.

Test reports must be promptly distributed to the concrete producer, as well as the contractor and engineer. This is essential to the timely resolution of problems.

References

1. ASTM Standards C 31, C 39, C 172, C 470, C 617, C 1077, and C 1231, ASTM Book of Standards, Volume 04.02,

American Society for Testing and Materials, West Conshohocken, PA.

2. Building Code Requirements for Reinforced Concrete, ACI 318, American Concrete Institute, Farmington Hills, MI.

3. Standard Specification for Structural Concrete, ACI 301, American Concrete Institute, Farmington Hills, MI.

4. In-Place Concrete Strength Evaluation--A Recommended Practice. NRMCA Publication 133, NRMCA, Silver Spring, MD.

5. Effect of Curing Condition on Compressive Strength of Concrete Test Specimens, NRMCA Publication 53, NRMCA Silver Spring, MD.

6. Review of Variables that Influence Measured Concrete Compressive Strength, David N. Richardson, NRMCA Publication 179,

NRMCA, Silver Spring, MD.

7. Low Strength Tests? Maybe Not! E.O. Goeb, Concrete Products, December 1992.

8. Why Low Cylinder Tests in Hot Weather? E.O. Goeb, Concrete Construction, Jan. 1986.

1982, 1989, 2000

![]()